Some times nuts are too much seized on screw or head is so much damaged or worn that they cannot be unscrewed with conventionnal wrench or socket.

So last solution is to destroy the nut to loosen the assembly. For this you can try using a saw or an angle grider but you risk to damage the screw and access may be difficult.

Nut splitter is a simple low cost tool that will do this work without above problems.

Working principle is based on a wedge that is pushed by mean of a screw and forces the nut to break.

Use is very simple, just put the nut you want to loosen in the hole of the tool and screw tool until the nut breaks. Do not overtighten to prevent damage to the threads under the nut.

When the screw is broken normaly it can be loosen without effort.

Electric planer is a very efficient tool to remove material from a wood board in order to adapt size or plane a rough surface.

Use is easier than manual planer and doesn't need to be an expert in blade sharpening.

Working principle is similar to milling machine, with a cylinder fitted with two blades that grind wood wile turning.

the electric planer can :

• Prepare raw wood before sanding to get a flat, leveled surface

• remove material for adjusting a part to a desired size

• chamfer an angle

• plane top or bottom of a door which doesn't fits well

• make a rabbet (machining in "L")

Settings :

Planer has a wheel for adjusting the depth of cut depending on the thickness of the wood to remove. The setting is usually done by steps of 0.1mm. Maximum depth depends of planer power.

use :

Use is very simple but still requires a little practice. Before using planer you must check that blades are in good condition because if they have an impact you will obtain a defect to the wood surface and if they are worn this will increase the effort necessary to move the planer and surface will not be smooth. You must also ensure that the wood is clean (no grit and without nails or metallic parts because the blades will be damaged if they hit this kind of objects).

Put the front of the tool on the surface to be planed, at this step blades must not be in contact with wood. The engine must be started before entering in wood. Then planer must be held firmly, pressing it forward. The feed rate must be constant without straining the engine. You have to cover in one time the entire length of the board, otherwise you will obtain some defect where you have stopped.

If board is larger than the planer you will have to do several successive passes but it will be difficult to get a perfectly smooth surface you may need to sand the part after.

Screwdriver's tip :

If you are equipped with an electrical wood planer think to buy raw sawn wood that is cheaper than plane one.

Concrete sander is working on same principle than conventional wood or metal sander except that the abrasive disc is replaced by one or two diamond wheels. This allows to sand or grind hard materials as concrete or stones.

This tool can be used for several application but due to its size it will be limited for small surfaces even if efficiency is quite impressive.

It can be used for :

- flattening or removing small defects on concrete slab

- polishing stone floor or pavement

- remove old tiles glue

- remove roughtcast on wall

In general it will be great on hard materials but will not work on soft surfaces as old carpet glue or thick paint.

Several different types of diamond wheels are available and to be selected according to work to be done.

This type of grinder will be usefull for diyers in home construction or renovation and will make works hardly possible without or far more longer by other means.

As it is very agressive, to obtain a good result procced by several steps without forcing on the tool. If you work inside, connect to sander a good vaccum cleaner as it generates huge amount of dust.

The only constraint will be the cost of the machine and replacement wheels even if they last quite long time. You can choose to rent one if you only forecast to use one but pay attention as diamond wheels are often not comprised in initial price. So it could be cheaper to buy one taking into account that you will have it for any future application or that you can sell it after.

Since few years a new type of drill bit is available on the market. This milling drill bit is made to be used both as a standard bit for normal drilling but also for small milling to enlarge a hole or make a goove or a fence.

Center part of the drill is replaced by many small teeth like a cilindrical wood-rape.

We decided to test one of these in order to check its real milling capabilities.

Test was made with 5 mm standard plywood.

For drilling operation, no diference was noticed compared to a conventional drill bit.

For milling / cutting, first part of the test was made using a cordless drill (12V ; 1200RPM capability). Even in 5 mm ply, result was quite disappointing, needing very long time to cut few milimeters. and consequent effort on the drill to progress in the wood.

Then we decided to install the bit on a normal drill (500W 2500RPM). Result was completly different with real milling capabilities and efficiency. This is mainly due to the higher rotation speed.

To conclude if you use a cordless drill, this type of drill bit will be limited to small work as enlarging diameter of a hole. But it will have more use with a more powerfull drill. It can be uses with wood and soft metals as aluminium, cooper or brass. The only limit will be the thinkness of the material (5 mm in metal and 2 cm in wood seems to be a realistic limit) as more you will increase thickness more the milling will be hard and long.

Anyway it can be usefull for DIYers if you don't have correct bit size or if you want to do oblong holes.

The electric towel radiator is an essential accessory in a modern bathroom. There are many models of any dimensions and shapes. However, the basic models are between 90 and 120 cm high and may be difficult to integrate into a small bathroom. It is of course possible to buy smaller one but the price quickly becomes prohibitive.

Design of electric towel radiators or central heating one made of steel allows a DIYer to adjust the height.

However this address only to people who can make a good welding (ARC, MIG, TIG or oxy-gas).

Note: if you use a brand new radiator forthis operation you will certainly loss the warranty, so it can be useful to test that heating is correct before modification.

This method can also be used for central heating radiator.

Materials needed:

• metal saw

• welder

• angle grinder

• paint

The first step is to drain the radiator and remove the electrical resistor in order to determine the heigth you can cut. (height reduction shall be limited to the minimum to maintain the efficiency of the radiator and prevent resistor to be oversized).

Then cut the two ends at about 1cm to keep for later the thread and caps. You can now cut the radiator to the desired length. Cuts should be clean and well perpendicular to the tube axis.

The most delicate operation is to weld back the caps on the radiator with no leak!. To keep original design you will have to grind the welds. If you have also cut the part with fitting for attachment you will also have to weld them to the top of the radiator.

To finish make paint touch-up on welds and fill the radiator with either the original liquid or car coolant.

Acetone is a solvent which may be useful for your DIY jobs. In most cases acetone replaces trichlorethylene which is hardly procurable.

Acetone h

as strong dissolving power.

The main uses are :

• Clean and degrease mechanical parts

• Clean surfaces before painting

• Remove glue residue (

before glue drying or curing)

• dilute some paint (car paint ...), varnish, or resins (epoxy and polyester) before application

• Clean utensils (brushes, spray guns ...) after use with the products mentioned above

• stripping some paint after drying (ex: paint in

spray)

• peel off stickers

Warning : acetone dissolves some plastics including polystyrene and polycarbonate and can damage painted surfaces, if in doubt do a preliminary test.

In order to prevent electrical and electronical devices dissassembly, manufacturers often use security screws with specific head shape. Fortunately you can buy security screw tips on the market. But if screw is embedded in a deep hole, in general the tips adapter is too large to go inside and it is impossible to reach the screw.

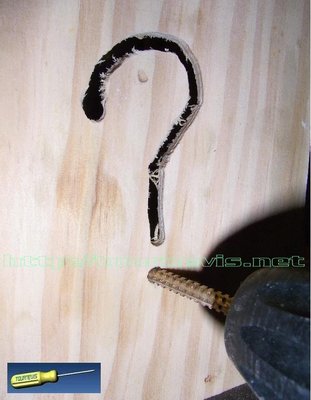

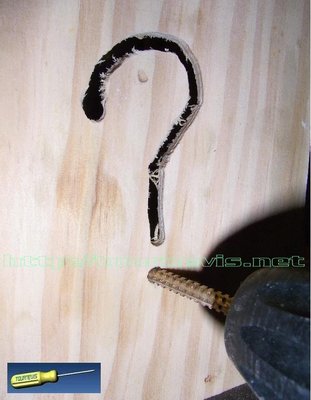

An easy method to solve this issue is to modify the screw tip in order to allow its use with a simple flat screwdriver.

For this you will have to make a groove at back of the tip. Pay attention to center it pretty well. Tip material is very hard you can try to make the groove with a metal hand saw but the best will be the use of a coridon disk fixed on a mini drill.

When done just put the screw tip inside the hole an use adapted flat screwdriver to unscrew.

At reassembly you can replace security screw by a standard one to ease any further reopening.